|

Address:No. 23 Dongsi Road, East development Zone, Linqu,Weifang City,Shandong Province,China |

|

Tel: +86-536-8309116 +86-532-86688809 |

|

Fax: +86-0536-8309116 |

|

Email: rechal@baitecidian.com |

- *Brand:Baite

- *Color:Multi Color

- *Voltage:22V

- *Weight:1T

- *Material:Stainless Steel

- *Warranty Period:1 Year

- *Country Of Origin:Shandong, China (Mainland)

- *After-Sales-Service:Technical Service

- *Dimension:Customized

- *Price:Negotation

Introduction:

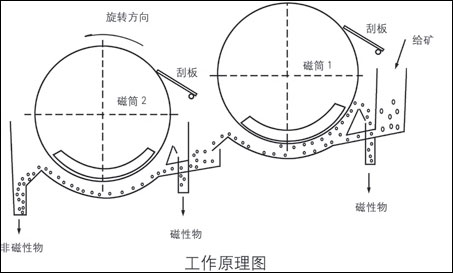

Magnetic separator is widely used in coal mine processing. With the development and expansion of heavy media processing technique,

drum separator for heavy media processing is widely used in coal-washing plant. The structure of coal mine used drum separator has never

had big change, while with the application of new magnetic material, magnet developed from simplex ferrite, mixed magnet to rare earth

super strength magnet. Magnetic intensity was raised greatly, improving the recovery percent and lowering media consuming effectively.

Features:

-- The same cylinder can match three tub, adapted to different sorting process.

-- Half counter-current slot is suitable for the ore particle size was 0.5-0 mm strong magnetic mineral wet roughing and select, especially suitable for big size

is 0.15 ~ 0 mm mineral selections.

-- Reflux tank is suitable for the ore particle size of 0.6 mm ~ strong magnetic mineral wet roughing and scavenging. Especially in the dense medium coal

preparation recycle, etc.

-- Downstream groove is suitable for the ore granularity is 6 ~ 0 mm roughing and selection.

-- Half counter-current slot and downstream groove are in series, improve the concentrate grade.

-- Magnetic system is made of high quality material or compounded with magnets, ferrite drum table magnetic induction intensity for an average of 100 ~ 600 mt.

-- According to user needs, can provide downstream, half counter-current type, counter-current etc.

-- Various different tables of strong magnetic separator in stock for fast delivery.

-- Our product has simple structure, large capacity, easy operation, easy maintenance, etc.

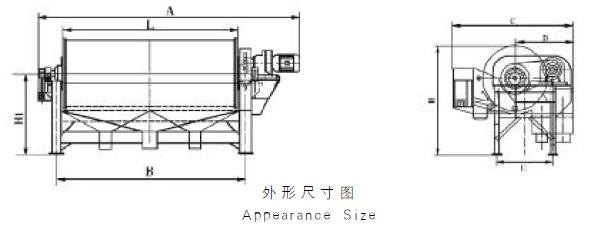

overal Dimension Drawing

Working Principle Drawing

Technical Parameter

| NO. | Model | Diameter of the drum (mm) | Length of the drum (mm) | Magnetic induction density(GS) | Capacity (T/h) | Appearance size (mm) | Driving Power(kw) | Roller rotating speed (r/min) | Weigh(kg) |

| 1 | XCTN-1012 | 1050 | 1200 | 1500-3000 | 50-160 | 2650×2170×1705 | 4 | 21 | 2600 |

| 2 | XCTN-1015 | 1500 | 70-200 | 2965×2170×1705 | 4 | 3200 | |||

| 3 | XCTN-1018 | 1800 | 90-260 | 3265×2170×1705 | 4 | 3700 | |||

| 4 | XCTN-1021 | 2100 | 120-300 | 3715×2170×1705 | 5.5 | 4200 | |||

| 5 | XCTN-1024 | 2400 | 150-400 | 4015×2170×1705 | 5.5 | 4900 | |||

| 6 | XCTN-1027 | 2700 | 180-350 | 4315×2170×1705 | 5.5 | 5500 | |||

| 7 | XCTN-1030 | 3000 | 230-400 | 4835×2170×1705 | 7.5 | 5900 | |||

| 8 | XCTN-1218 | 1200 | 1800 | 130-320 | 3265×2380×1935 | 5.5 | 16 | 4300 | |

| 9 | XCTN-1224 | 2400 | 190-380 | 4015×2380×1935 | 7.5 | 5600 | |||

| 10 | XCTN-1230 | 3000 | 280-460 | 4835×2380×1935 | 7.5 | 6400 | |||

| Note:The strength of the magnetic field can be customized according to customer requirements,from 800gs-10000gs.piease indicate in the contract. | |||||||||