|

Address:No. 23 Dongsi Road, East development Zone, Linqu,Weifang City,Shandong Province,China |

|

Tel: +86-536-8309116 +86-532-86688809 |

|

Fax: +86-0536-8309116 |

|

Email: rechal@baitecidian.com |

The buckets are usually where the chain or belt path is vertical or steeply inclined in a single plane. The buckets are returned back down to a tail pulley or sprocket at the bottom.There are four broad classifications of bucket elevators: centrifugal, continuous, positive, and internal discharge. The most commonly used are the centrifugal and

continuous discharge elevators.

- *Brand:Baite

- *Color:Multi Color

- *Voltage:220V/Customized

- *Weight:1T

- *Material:Stainless Steel

- *Warranty Period:1 Year

- *Country Of Origin:Shandong, China (Mainland)

- *After-Sales-Service:Technical Service

- *Dimension:Customized

- *Price:Negotation

Introduction:

Bucket elevators are designed to move flowing powders or bulk solids vertically. Bucket elevators use an endless belt or chain and have a series of buckets attached to

it. Bulk material is spread into an inlet hopper. Buckets (or cups) dig into the material and convey it up and over the head sprocket/pulley, and then throw the material

out a discharge throat.

Bucket elevators are not self-feeding, and are fed at a controlled rate. The buckets are usually where the chain or belt path is vertical or steeply inclined in a single plane.

The buckets are returned back down to a tail pulley or sprocket at the bottom.

There are four broad classifications of bucket elevators: centrifugal, continuous, positive, and internal discharge. The most commonly used are the centrifugal and

continuous discharge elevators.

Feature:

(1) Wide range of ascension. This kind of elevator has fewer requirements for material’s kind, specialty and shape size. Not only can lift the general powder, small

granule materials, but also can promote the larger grinding cut materials. Material temperature should lower than 250 °C.

(2) Big carrying ability. Lifting capacity is 15m³/h-800 m³/h.

(3) Low energy consumption. The energy it consumes is 25%-45% of chain elevator.

(4) Long service life. The transmission chain service life is more than 5 years.

(5) High hoisting height. It has low operation speed, stable in operating. Also it applies high plate chain with strength wear-resisting, so it can achieve high hoisting height.

(6) Good sealing, little environmental pollution.

(7) Good operating reliability. Advanced design principle and processing method, ensure the reliability of the machine running.

(8) Easy operation and maintenance, less easily damaged parts.

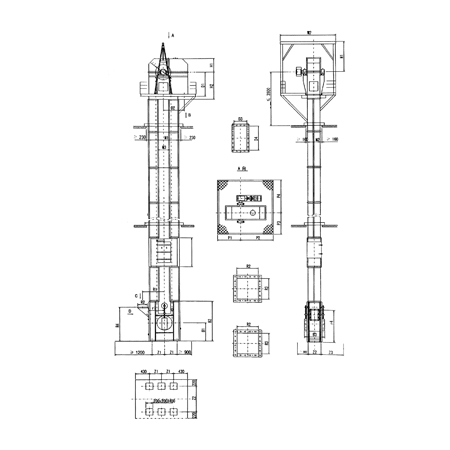

overal Dimension Drawing

Technical Parameter

| Mode | Capacity(m³/h) | Max Paticle size(mm) | ||||

| percentage% | ||||||

| 50 | 25 | 50 | 75 | 100 | ||

| NE15 | 15 | 65 | 50 | 40 | 30 | 25 |

| NE30 | 32 | 60 | 75 | 58 | 47 | 40 |

| NE50 | 60 | 90 | 75 | 58 | 47 | 40 |

| NE100 | 110 | 130 | 105 | 80 | 65 | 55 |

| NE150 | 170 | 130 | 105 | 80 | 65 | 55 |

| NE200 | 210 | 170 | 135 | 10 | 85 | 70 |

| NE300 | 320 | 170 | 135 | 10 | 85 | 70 |

| NE400 | 380 | 205 | 165 | 125 | 105 | 90 |

| NE500 | 470 | 240 | 190 | 145 | 120 | 100 |

| NE600 | 600 | 240 | 190 | 145 | 120 | 100 |

| NE800 | 800 | 275 | 220 | 165 | 135 | 110 |

Coontact us

Whatsapp:+86 18765753862 Miss Rechal